中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

The lifespan of a stage hoist can vary depending on several factors, including usage patterns, load capacities, environmental conditions, maintenance practices, and the overall quality of the hoist. Here are some general considerations:

Usage Frequency:

The more frequently a stage hoist is used, the faster its components may experience wear and tear. Hoists used for daily performances or in busy event venues may have a shorter lifespan compared to those used infrequently.

Load Capacity:

The load capacity of the hoist is a critical factor. Hoists operating near or at their maximum rated load may experience more stress and wear on components, potentially leading to a shorter lifespan. It's essential to operate the hoist within its specified load limits.

Environmental Conditions:

The working environment plays a significant role. Hoists used in harsh environments, such as those with high humidity, corrosive substances, or extreme temperatures, may experience accelerated wear. Proper protection and maintenance can mitigate these effects.

Maintenance Practices:

Regular maintenance can extend the lifespan of a stage hoist. Routine inspections, lubrication, and timely replacement of worn components are essential. Neglecting maintenance can lead to premature wear and potential breakdowns.

Quality of Components:

The overall quality of the hoist, including the materials used and manufacturing standards, can impact its durability. High-quality components and construction are likely to result in a longer lifespan.

Manufacturer's Reputation:

The reputation of the hoist manufacturer matters. Established and reputable manufacturers often produce hoists that undergo rigorous testing and adhere to industry standards, contributing to longer lifespans.

Compliance with Standards:

Hoists that comply with safety and industry standards are designed for reliable and safe operation. Compliance ensures that the hoist meets certain criteria for structural integrity, safety features, and performance.

Proper Installation:

Correct installation by qualified professionals is crucial. Poorly installed hoists may experience premature wear or failures. Ensure that the hoist is installed according to the manufacturer's specifications and local regulations.

In general, a well-maintained and properly used stage hoist can have a lifespan ranging from several years to over a decade. However, it's important to note that each hoist is unique, and its actual lifespan will depend on the specific conditions and factors mentioned above. Regular inspections, adherence to load limits, and following manufacturer guidelines for maintenance contribute to maximizing the lifespan of a stage hoist.

This stage electric hoist is developed for commercial performance stages, weddings, shopping malls, and various entertainment venues.

feature is:

1. High-efficiency, light-weight motor, asbestos-free braking system, low energy consumption.

2. Stamped steel shell, light and strong.

3. High-strength safety hook will not break when subjected to accidental overload impact, and will only gradually deform when overweight.

4. Lightweight, beautiful and durable plastic chain bag.

5. Limit switch: There are limit switch devices on the top and bottom of the hoist to stop the motor automatically and prevent the chain from exceeding, ensuring safety.

6. Heat-treated steel chain guide plate.

7. Easy to operate and maintain.

8. Designed for both forward and reverse directions and all-weather use.

9. It is equipped with an adjustable spiral limit switch and has high reliability and performance.

10. The chain is galvanized and not easy to rust.

11. Lubricating grease is installed in the gear box to prevent oil droplets from penetrating into the stage.

12. The hoist's motor is sealed in an aluminum steel ring cylindrical shell to protect the motor.

13. Suitable for connecting with various controllers and circuit distributors.

14. Double braking system to ensure safe operation.

Composition and introduction:

Electric Motor: Electric motors provide the power needed to lift and lower loads. It is usually electric and may include features such as variable speed control.

Gear train: The gear train is responsible for transmitting the rotational motion of the motor to the lifting mechanism. It consists of gears that increase torque and decrease speed as needed.

Lift Mechanism: This component directly engages the load and moves it up or down. It usually consists of a drum or pulley system around which a lifting cable or chain is wound.

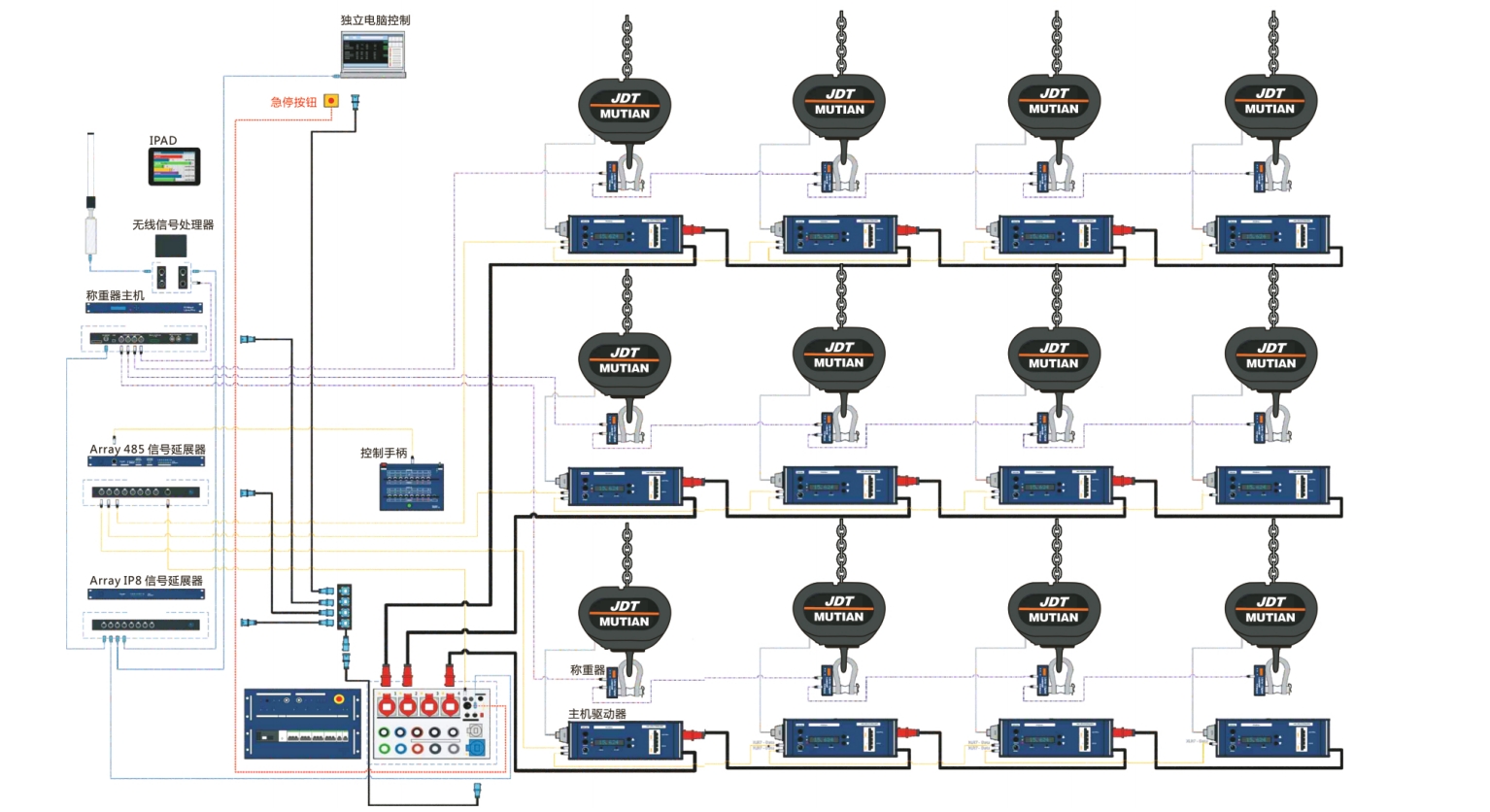

Control System: The control system allows the operator to regulate the operation of the hoist, including starting, stopping, and adjusting the speed and direction of movement. It may include a control panel, console, or remote control device.

Safety features: The stage electric hoist is equipped with a variety of safety mechanisms to prevent accidents and protect equipment and personnel. These features may include overload protection, limit switches to prevent overtravel, emergency stop buttons and safety brakes.

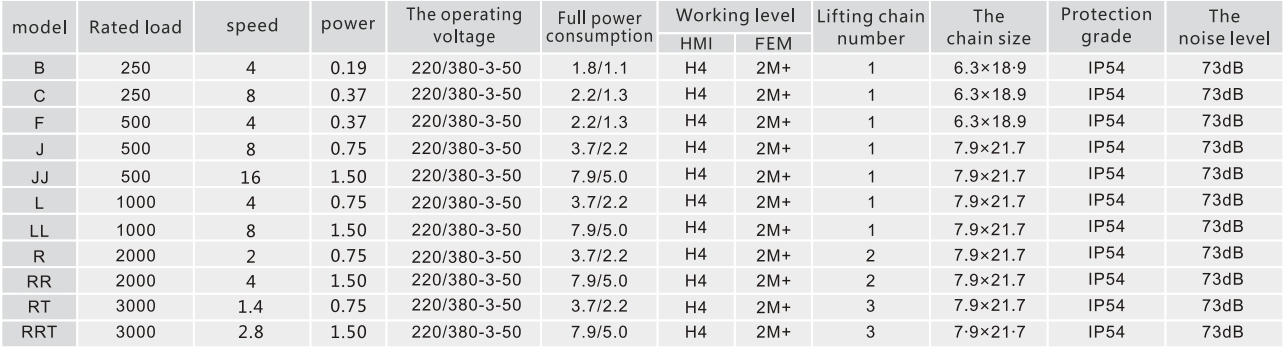

Parameters of stage electric hoist:

Controller features:

The controllers are suitable for electric hoists to directly control the motor. Single electric hoist controllers can be provided upon request; panel control or handle control is available:

·Can be controlled individually or in groups, each channel has an up/down selection switch, and a "run" button activates all pre-selected circuits

With leakage protection device and phase conversion function;

emergency braking;

Specially designed multiple compartments can place tools, wires and other electrical supplies.

Due to the perfect combination of motor + computer intelligent control system, this electric hoist can not only be manually controlled, but also can be connected to the computer controller for remote group control, making it relatively easy for technicians to operate.

Computer intelligent control system:

1. Variable frequency drive series: Suitable for touring performances, variable frequency drive can create changing stage effects. The dual brake system H4 working level motor is matched with a computer-programmed drive control system, which is suitable for the modeling needs of large-scale performances. 2. Fixed speed drive series: Fixed speed drive, suitable for various performance activities that require efficient synchronization, automatic alarm and computer display reminder, efficient and safe. It can also be linked with DMX and MIDI consoles.

The stage electric hoist and motor + computer intelligent control system are perfectly combined and relatively easy for technicians to operate, and technicians only need little physical labor. They can be controlled remotely, allowing operators to adjust settings from a distance.

X