中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

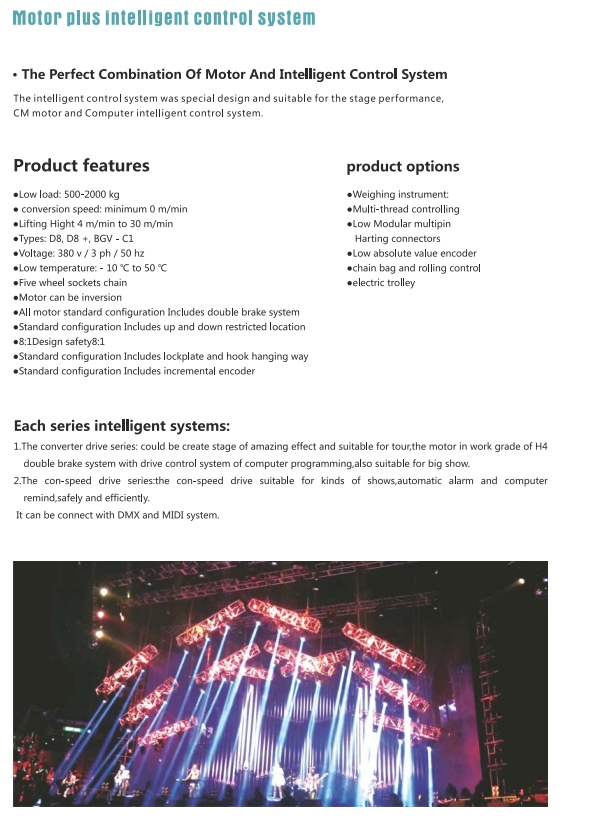

The working principle of a stage electric crane, also known as a stage electric hoist or electric chain hoist, involves several key components working together to lift and move loads in a controlled manner. Here's a general overview of the working principle:

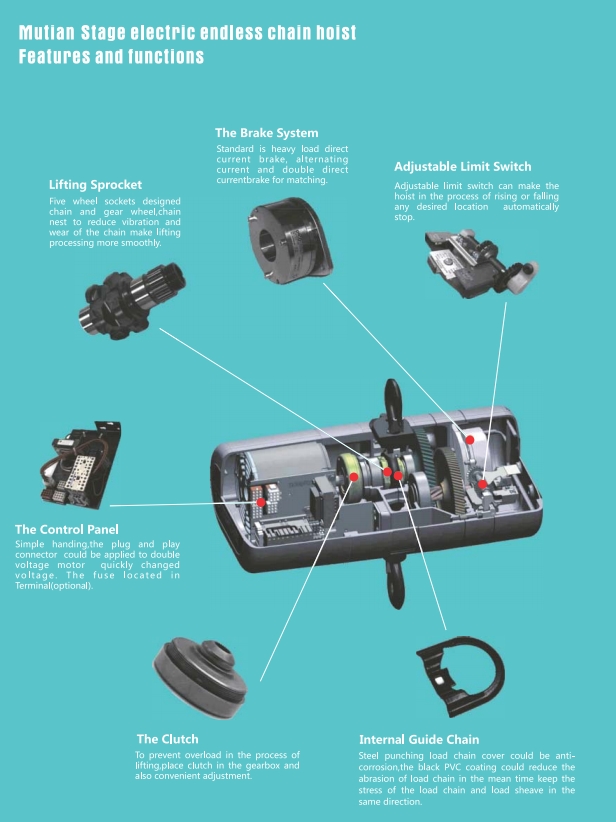

Electric Motor:

The crane is equipped with an electric motor, which is the primary power source. The motor can be either an alternating current (AC) motor or a direct current (DC) motor. It provides the necessary mechanical power to drive the lifting mechanism.

Gearbox and Transmission:

The electric motor is connected to a gearbox or transmission system. The gearbox helps control the speed and torque of the motor's output. This allows for adjustments to match the requirements of lifting and moving different loads.

Brake System:

A brake system is incorporated to ensure that the crane can stop and hold its position when required. This is crucial for safety and prevents unintentional movements of the load when the motor is not actively lifting.

Lifting Mechanism (Chain or Wire Rope):

The lifting mechanism, which can be a chain or wire rope, is wound around a drum or sprocket connected to the motor. When the motor operates, it rotates the drum, causing the lifting mechanism to spool and lift the load.

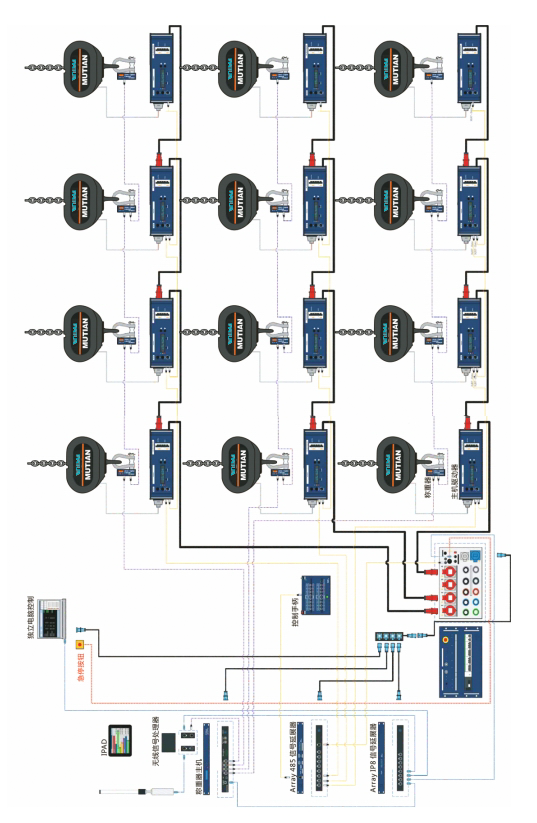

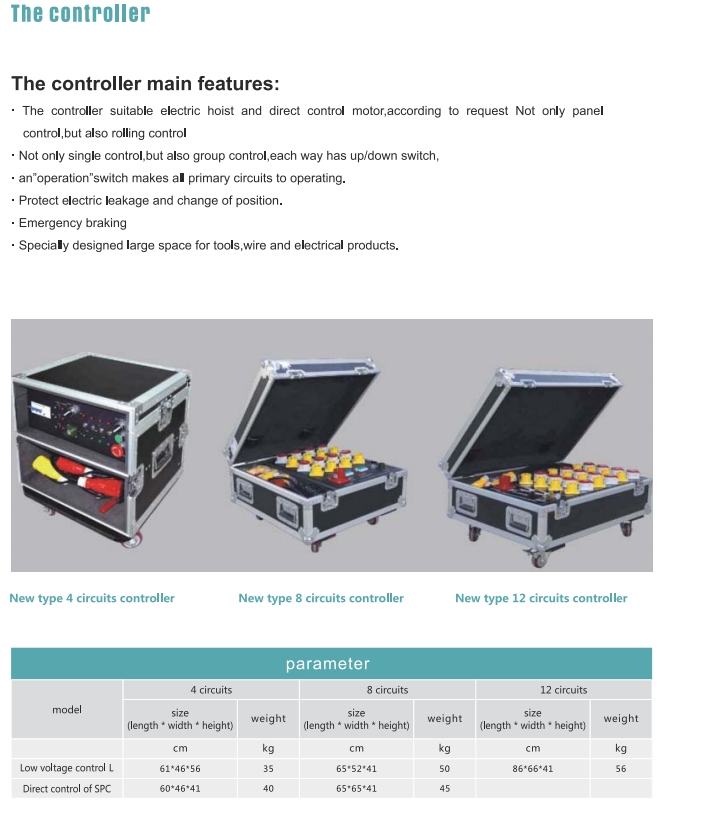

Control System:

The crane is equipped with a control system that allows the operator to command and control the movements of the crane. This can be achieved through a control pendant or a remote control device, which includes buttons or switches for various functions.

Limit Switches:

Limit switches are integrated into the crane to set upper and lower limits for the travel of the load. These switches help prevent overtravel and ensure that the load is lifted or lowered within safe parameters.

Electrical Components and Wiring:

Various electrical components, such as relays, contactors, and wiring, are used to control the electrical circuits and functions of the crane. These components facilitate the communication between the control system and the electric motor.

Housing or Casing:

The internal components of the crane are enclosed in a housing or casing. This protective covering not only safeguards the internal mechanisms from external elements but also provides structural support to the crane.

Suspension and Mounting:

The crane may include components for suspension or mounting, such as brackets, trolleys, or other mechanisms. These components allow the crane to be attached to a support structure and provide mobility within the working area.

In operation, the operator uses the control device to command the crane to lift, lower, and move loads horizontally. The integration of safety features, such as brakes and limit switches, ensures safe and precise control during the lifting and positioning of loads on the stage.

X