中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

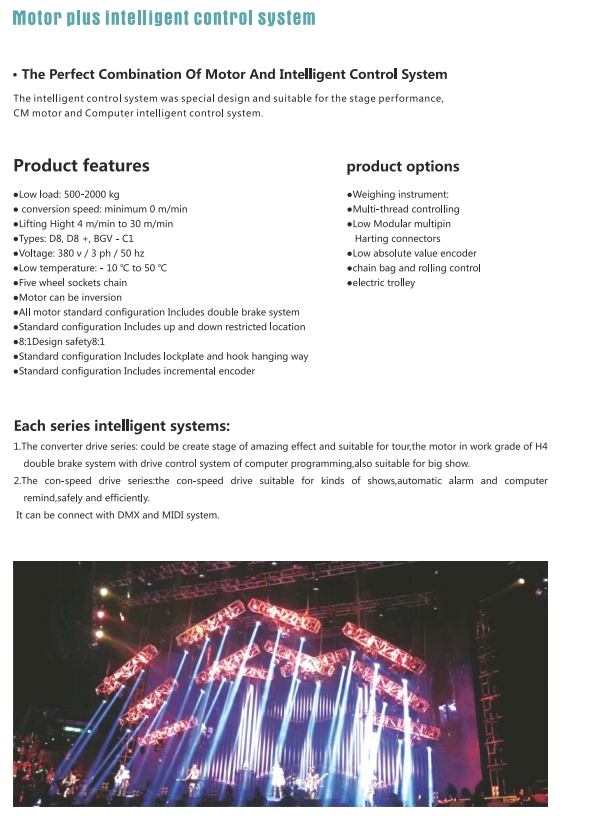

The internal structure of a stage electric hoist can vary based on the specific model and manufacturer. However, I can provide a general overview of the common components found in a typical electric hoist used in stage applications:

Electric Motor:

The electric motor is a fundamental component responsible for powering the hoist. It provides the necessary mechanical force to lift and lower loads.

Gearbox:

The gearbox is often included to control the speed and torque of the electric motor. It helps optimize the hoist's performance based on the load requirements.

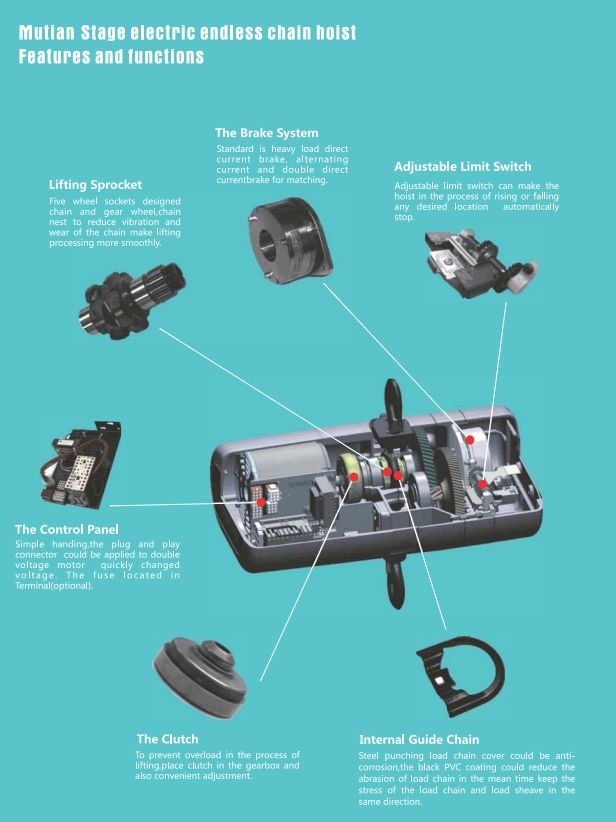

Brake System:

A brake system is incorporated to ensure that the hoist can stop and hold a load securely in place. Common brake types include disc brakes or drum brakes.

Drum or Chain Wheel:

The drum or chain wheel is where the lifting medium (such as a wire rope or chain) is wound. As the drum rotates, it raises or lowers the load.

Lifting Medium (Wire Rope or Chain):

The lifting medium is a crucial part of the hoist, providing the connection between the load and the hoist mechanism. It could be a wire rope or a chain, depending on the hoist design.

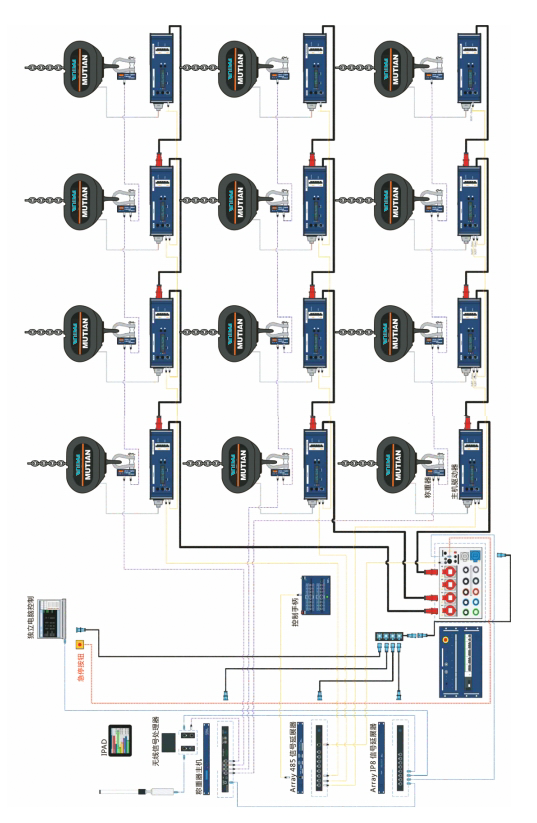

Control System:

The control system consists of various components for operating the hoist. This may include a control panel, buttons, switches, or a remote control device. Advanced systems may have programmable features.

Limit Switches:

Limit switches are installed to define the upper and lower travel limits of the hoist. They prevent overtravel and ensure that the hoist stops when it reaches a predetermined position.

Load Sensors (Optional):

Some modern electric hoists may be equipped with load sensors to monitor the weight of the load being lifted. This information can contribute to safe and efficient operation.

Overload Protection:

Overload protection mechanisms are designed to prevent the hoist from lifting loads beyond its rated capacity. This protects the hoist from damage and enhances safety.

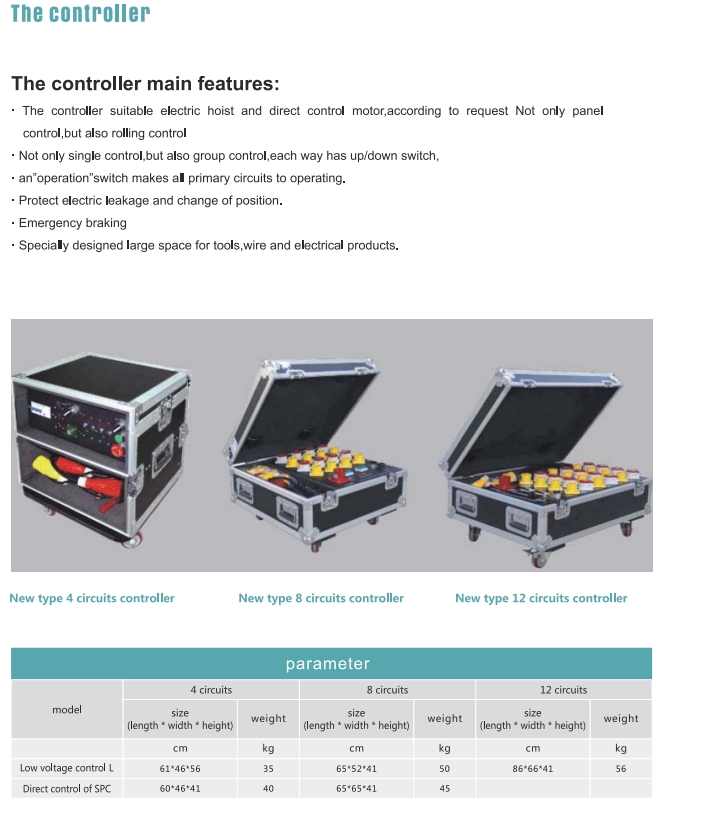

Emergency Stop System:

An emergency stop system is a critical safety feature that allows for immediate halting of hoist operations in case of an emergency.

Housing and Frame:

The housing or frame encases the internal components, providing protection and support. The design of the housing may vary based on factors such as the environment of use and load capacity.

Power Supply:

The hoist is connected to a power supply, usually electricity, to energize the electric motor and enable the lifting and lowering functions.

It's important to note that the internal structure can vary, and the features mentioned above may be arranged differently or may not be present in all hoists. For detailed information about a specific stage electric hoist model, it's recommended to refer to the manufacturer's documentation or user manual.

X