中文版

中文版

Welcome to contact us by phone:0086-0312-7969888

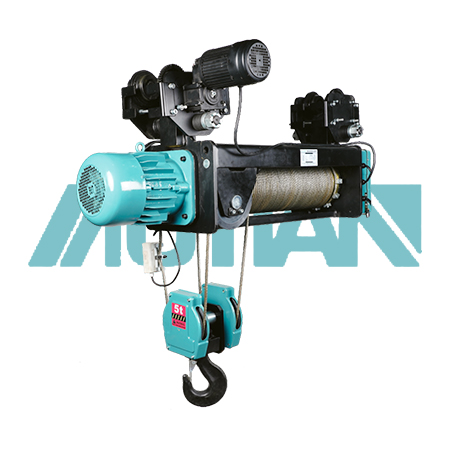

A wire rope electric lift, also known as an electric hoist, is a device used for lifting and lowering heavy loads in various industrial and commercial applications. It consists of a motor-driven mechanism that utilizes a wire rope (made of strands of steel wires wound together) to lift objects vertically or to move them horizontally along a track.

Here's an introduction to the key components and functioning of a wire rope electric lift:

Motor: At the heart of the electric lift is an electric motor. This motor provides the power necessary to drive the lifting mechanism. Depending on the size and capacity of the lift, different types of motors may be used, including AC or DC motors.

Gearbox: In most electric lifts, the motor's rotational motion is transmitted to the lifting mechanism via a gearbox. The gearbox helps to increase the torque output while reducing the rotational speed to a level suitable for lifting heavy loads effectively.

Drum or Sheave: The wire rope is wound around a drum or sheave, which is directly connected to the motor or gearbox. As the motor rotates, the drum or sheave winds or unwinds the wire rope, lifting or lowering the load accordingly.

Wire Rope: The wire rope is a critical component of the electric lift, responsible for bearing the weight of the load. It is typically made of multiple strands of steel wire twisted or braided together to form a strong and flexible rope capable of withstanding heavy loads.

Hook or Lifting Attachment: At the end of the wire rope, there is usually a hook or other lifting attachment mechanism. This is where the load is attached for lifting or lowering. Hooks often come with safety latches to prevent accidental detachment of the load.

Control System: Electric lifts are typically equipped with a control system that allows operators to control the lifting process. This may include simple pendant controls with buttons for raising, lowering, and stopping the lift, or more advanced systems such as remote controls or integrated control panels.

Safety Features: Safety is paramount in electric lifts. Various safety features may be incorporated, including overload protection to prevent the lift from lifting loads beyond its rated capacity, limit switches to control the travel of the lift, emergency stop buttons, and brake systems to hold the load in place when the lift is not in operation.

Wire rope electric lifts offer several advantages, including high lifting capacities, smooth and precise operation, versatility in various environments, and relatively easy installation and maintenance. They are commonly used in industries such as construction, manufacturing, warehousing, and logistics for tasks ranging from loading and unloading goods to moving heavy machinery and equipment.

X